Elevator machines are the heart of every elevator system, responsible for transporting people and goods up and down buildings. Two popular types of elevator machines are gearless traction and geared traction, each with its own advantages and disadvantages.

Gearless traction elevator machines use a large drum, called a sheave, to raise and lower elevator cars. These machines are typically found in high-rise buildings and are known for their energy efficiency and quiet operation. Instead of gears, gearless machines use a powerful electric motor to drive the sheave directly, which allows them to be more efficient than geared machines.

One of the key benefits of gearless traction elevator machines is their energy efficiency. By using a direct-drive system, gearless machines can eliminate the energy loss that occurs in geared machines due to the friction of the gears. As a result, gearless machines can be up to 70% more efficient than geared machines, which can translate into significant cost savings over time.

Another advantage of gearless traction elevator machines is their quiet operation. Since they don't rely on gears, which can generate noise and vibration, gearless machines are virtually silent, making them a popular choice for high-end residential and commercial buildings where noise levels are a concern.

However, gearless traction elevator machines also have some drawbacks. They are typically more expensive to install and maintain than geared machines, which can make them less cost-effective for smaller buildings or budget-conscious projects. In addition, gearless machines require a larger motor and more powerful electrical supply, which can make them more difficult to integrate into older buildings or retrofit projects.

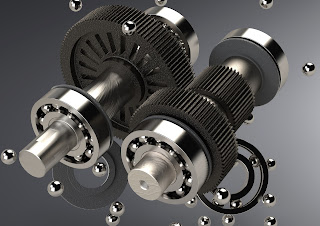

Geared traction elevator machines, on the other hand, use a gearbox to transmit power from the electric motor to the sheave. These machines are generally less expensive and more versatile than gearless machines, making them a popular choice for low- to mid-rise buildings.

One of the key benefits of geared traction elevator machines is their flexibility. Since they use a gearbox, which can be designed to provide different gear ratios, geared machines can be customized to fit a wide range of building types and elevator applications. This makes them a popular choice for buildings with unusual dimensions or elevator requirements.

Another advantage of geared traction elevator machines is their ease of maintenance. Since geared machines use a simple gearbox to transmit power, they are generally easier to repair and maintain than gearless machines. In addition, geared machines tend to have a longer lifespan than gearless machines, which can make them a better investment over the long term.

However, geared traction elevator machines also have some disadvantages. They tend to be less energy-efficient than gearless machines, which can result in higher operating costs over time. In addition, geared machines are typically louder and generate more vibration than gearless machines, which can be a concern in some building environments.

Both gearless traction and geared traction elevator machines have their own unique advantages and disadvantages. Gearless machines are generally more efficient and quieter than geared machines, but they can be more expensive and difficult to integrate into older buildings. Geared machines, on the other hand, are more flexible and easier to maintain than gearless machines, but they are generally less energy-efficient and noisier. When choosing an elevator machine, it's important to consider the specific needs and constraints of the building and elevator system, as well as the long-term costs and benefits of each option.

Elevator Companies Manufacturers - Snippets on Escalators, Freight Elevators, Car Automobile Lifts, Car Parking Systems and Passenger Elevators in Kerala.

Sunday, April 23, 2023

Gearless Traction and Geared Traction Elevator Machines

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment