Elevator machines are the heart of every elevator system, responsible for transporting people and goods up and down buildings. Two popular types of elevator machines are gearless traction and geared traction, each with its own advantages and disadvantages.

Gearless traction elevator machines use a large drum, called a sheave, to raise and lower elevator cars. These machines are typically found in high-rise buildings and are known for their energy efficiency and quiet operation. Instead of gears, gearless machines use a powerful electric motor to drive the sheave directly, which allows them to be more efficient than geared machines.

One of the key benefits of gearless traction elevator machines is their energy efficiency. By using a direct-drive system, gearless machines can eliminate the energy loss that occurs in geared machines due to the friction of the gears. As a result, gearless machines can be up to 70% more efficient than geared machines, which can translate into significant cost savings over time.

Another advantage of gearless traction elevator machines is their quiet operation. Since they don't rely on gears, which can generate noise and vibration, gearless machines are virtually silent, making them a popular choice for high-end residential and commercial buildings where noise levels are a concern.

However, gearless traction elevator machines also have some drawbacks. They are typically more expensive to install and maintain than geared machines, which can make them less cost-effective for smaller buildings or budget-conscious projects. In addition, gearless machines require a larger motor and more powerful electrical supply, which can make them more difficult to integrate into older buildings or retrofit projects.

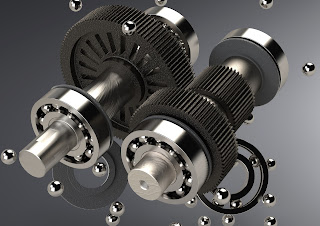

Geared traction elevator machines, on the other hand, use a gearbox to transmit power from the electric motor to the sheave. These machines are generally less expensive and more versatile than gearless machines, making them a popular choice for low- to mid-rise buildings.

One of the key benefits of geared traction elevator machines is their flexibility. Since they use a gearbox, which can be designed to provide different gear ratios, geared machines can be customized to fit a wide range of building types and elevator applications. This makes them a popular choice for buildings with unusual dimensions or elevator requirements.

Another advantage of geared traction elevator machines is their ease of maintenance. Since geared machines use a simple gearbox to transmit power, they are generally easier to repair and maintain than gearless machines. In addition, geared machines tend to have a longer lifespan than gearless machines, which can make them a better investment over the long term.

However, geared traction elevator machines also have some disadvantages. They tend to be less energy-efficient than gearless machines, which can result in higher operating costs over time. In addition, geared machines are typically louder and generate more vibration than gearless machines, which can be a concern in some building environments.

Both gearless traction and geared traction elevator machines have their own unique advantages and disadvantages. Gearless machines are generally more efficient and quieter than geared machines, but they can be more expensive and difficult to integrate into older buildings. Geared machines, on the other hand, are more flexible and easier to maintain than gearless machines, but they are generally less energy-efficient and noisier. When choosing an elevator machine, it's important to consider the specific needs and constraints of the building and elevator system, as well as the long-term costs and benefits of each option.

Elevator Companies Manufacturers - Snippets on Escalators, Freight Elevators, Car Automobile Lifts, Car Parking Systems and Passenger Elevators in Kerala.

Sunday, April 23, 2023

Gearless Traction and Geared Traction Elevator Machines

Sunday, April 16, 2023

A Brief On The Vertical Transport Industry

The vertical transport industry is a vital part of modern infrastructure and plays a crucial role in transporting people and goods from one level to another. This industry encompasses a wide range of systems that enable movement between different floors of buildings, as well as in industrial and mining applications. The vertical transport industry includes elevators, escalators, dumbwaiters, material lifts, and other mechanical systems that allow for the efficient and safe movement of people and goods.

Elevators are perhaps the most well-known and common form of vertical transport. They are used in a variety of settings, from high-rise office buildings and apartment complexes to hospitals and shopping malls. Elevators rely on a system of cables and pulleys to transport people and goods between floors. They are designed to be safe, reliable, and energy-efficient, and are subject to stringent safety standards to ensure their continued safe operation.

Escalators are another type of vertical transport commonly found in public spaces like shopping malls, airports, and train stations. They consist of a moving staircase that carries people up or down between different levels. Escalators are often preferred over elevators in high-traffic areas because they can move a larger number of people more quickly and efficiently. They are also energy-efficient and relatively low-maintenance.

Dumbwaiters are a type of small elevator used to transport goods rather than people. They are commonly found in restaurants and hotels, where they are used to transport food and other items between different levels. Material lifts are another type of vertical transport used primarily in industrial settings. They are used to move heavy loads like pallets and equipment between different levels of a factory or warehouse.

The vertical transport industry has come a long way since the first elevators were introduced in the mid-19th century. Today, elevators are equipped with advanced safety features like emergency brakes and backup power supplies to ensure that they continue to operate even in the event of a power failure. They are also designed to be energy-efficient, with features like regenerative braking and smart controls that optimize energy usage.

The vertical transport industry is an essential part of modern infrastructure and plays a vital role in enabling the efficient movement of people and goods. As buildings continue to grow taller and more complex, the need for safe, reliable, and energy-efficient vertical transport systems will only increase. As a result, the industry is likely to continue to evolve and innovate in the years ahead, with new technologies and designs that make vertical transport even safer and more efficient.

Friday, April 7, 2023

Moving Walkways | Travelators | Moving Sidewalks

Moving walkways, also known as travelators or moving sidewalks, have become a common feature in many airports, train stations, and other transportation hubs. These mechanized walkways allow passengers to move quickly and efficiently between destinations, while also reducing congestion and improving overall mobility. In this article, we'll take a closer look at the history and technology behind moving walkways, as well as their benefits and drawbacks.

History and Technology

The concept of a moving walkway dates back to the late 19th century, when inventors began experimenting with various mechanical conveyance systems. In 1893, for example, the Chicago World's Fair featured a moving sidewalk that transported visitors across a distance of approximately 2,000 feet. However, it wasn't until the mid-20th century that moving walkways became a practical and widespread form of transportation.

Modern moving walkways rely on a combination of mechanical and electrical systems to function. The walkway itself consists of a series of conveyor belts or metal plates that are driven by electric motors. These belts or plates are typically made from durable materials such as rubber or steel, and are designed to withstand heavy use and foot traffic.

The speed of a moving walkway can vary depending on the specific design and application. Some walkways move at a relatively slow pace of 1 to 2 miles per hour, while others can reach speeds of up to 6 miles per hour. The length of a walkway can also vary depending on the specific location and purpose, with some systems extending for hundreds of feet or more.

Benefits of Moving Walkways

There are several key benefits to using moving walkways for transportation. One of the main advantages is speed and efficiency. Moving walkways allow passengers to quickly move between different areas of a transportation hub without having to walk long distances or navigate complex routes. This can help to reduce travel times and increase overall mobility.

Another benefit of moving walkways is improved accessibility. These systems can be particularly useful for individuals with mobility impairments or disabilities, as they provide a convenient and accessible way to move between different areas of a transportation hub. Additionally, moving walkways can help to reduce congestion and alleviate overcrowding in busy transportation hubs, which can improve overall safety and comfort for passengers.

Drawbacks of Moving Walkways

While moving walkways offer many benefits, there are also some potential drawbacks to consider. One of the main concerns is safety. Moving walkways can be hazardous if not used properly, particularly for young children, elderly individuals, or those with mobility impairments. It's important to follow all posted safety guidelines and use caution when boarding or exiting a moving walkway.

Another potential drawback of moving walkways is energy consumption. These systems require significant amounts of electricity to operate, which can contribute to overall energy consumption and greenhouse gas emissions. Additionally, the maintenance and upkeep of moving walkways can be expensive, particularly in high-traffic areas.

Conclusion

Moving walkways are a popular and convenient form of transportation in many transportation hubs. These systems offer numerous benefits, including increased speed, improved accessibility, and reduced congestion. However, there are also some potential drawbacks to consider, including safety concerns and energy consumption. Ultimately, the decision to use moving walkways should be based on the specific needs and priorities of the transportation hub and its passengers.